At Rovita Green Energy LLP, we follow a state-of-the-art manufacturing process that ensures every biomass pellet we produce is consistent, high-quality, and eco-friendly.

Our production facility is designed with modern technology and strict quality control to guarantee that our pellets meet global standards.

Raw Material Collection Agricultural residues, sawdust, and forestry by-products are collected from trusted suppliers, farmers, FPOs.

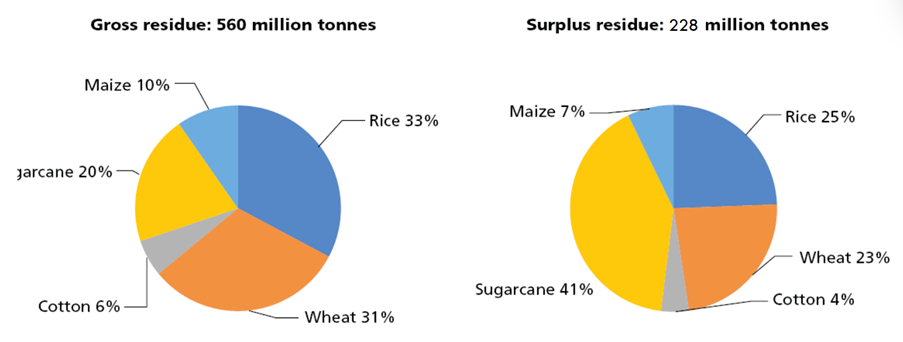

Source: NTPC

The raw material is dried to ≤14% moisture content for efficient burning and less smoke.

Dried biomass is ground into fine powder to ensure uniformity.

The biomass powder is compressed into 6–8 mm diameter pellets.

Fresh pellets are cooled to harden and stabilize.

Dust & broken pellets removed; tested for ash, calorific value, density.

Packed in 20kg bags, jumbo bags, or bulk dispatch.